One of the most popular ESD products, anti static gloves is made out of several different materials, all of which protect both the worker and the product from damage. Read More…

Gordon Brush’s® ESD & cleanroom products meet the specific needs of the electronics industry plus industries where static electricity buildup is detrimental to manufacturing.

TAKK Industries manufactures static eliminators for industrial processes and business machines. We also offer a full line of static eliminator blowers, spray, static detection meters and anti-static brushes. Some applications they can be used for are painting, plastic, textiles and more. If you have questions or need to meet certain specifications, don’t hesitate to contact TAKK Industries.

At Amstat Industries, we specialize in providing innovative solutions for static elimination, helping industries maintain optimal efficiency and safety in their operations. Our expertise lies in designing and manufacturing advanced static eliminators that effectively mitigate the challenges posed by electrostatic charges in a variety of industrial environments.

More Anti Static Glove Manufacturers

Anti Static Gloves: Comprehensive Guide for ESD Protection and Static Control

Anti static gloves play a critical role in modern manufacturing, assembly, and electronics industries by suppressing electrostatic charges while being worn by individuals handling delicate, static-sensitive materials. These static eliminators are engineered to safely dissipate static electricity without relying on chemical treatments, ensuring both the safety of components and the comfort of personnel.

Used extensively in electronics manufacturing, semiconductor fabrication, laboratories, and cleanroom environments, anti static gloves are essential for protecting sensitive devices and reducing the risk of costly damage due to electrostatic discharge (ESD). Whether assembling circuit boards, handling medical equipment, working with optical components, or repairing computers and cell phones, anti static gloves are a vital part of ESD-safe workspaces.

What Are Anti Static Gloves?

Anti static gloves—sometimes called ESD gloves, static dissipative gloves, or electrostatic control gloves—are specialized hand protection designed to prevent the build-up and discharge of static electricity. Unlike conventional gloves, ESD gloves are constructed using materials that safely conduct or dissipate static charges, ensuring that workers do not inadvertently transfer damaging electricity to sensitive products.

These gloves are widely used in industries where the control of static is paramount, including:

- Electronics assembly and repair

- Semiconductor manufacturing

- Medical device production

- Telecommunications

- Aerospace engineering

- Optics and photonics

- Cleanroom operations

- Photo labs and imaging equipment handling

- Petrochemical facilities

- Precision instrument manufacturing

- Electrostatic painting and powder coating

Key Features and Materials

When researching anti static gloves for electronics, it’s essential to understand the range of materials and designs available. The most common anti static glove materials include:

- Nitrile: Durable, comfortable, and latex-free, nitrile ESD gloves are ideal for environments where allergies are a concern.

- Carbon Nylon Knit: A porous, breathable fabric often combined with conductive carbon fibers to ensure uniform resistivity.

- PVC (Polyvinyl Chloride): Thin anti static PVC pads are stitched into key grip areas—such as the palm, inner thumb, and fingers—to improve both static dissipation and handling performance.

- Latex: Some latex-based anti static gloves are processed with chlorinated washing to minimize contamination and particle shedding, making them suitable for cleanroom and laboratory use.

- Filament Conductive Fiber: Integrated directly into the glove fabric, these fibers provide consistent, uniform resistivity and reliable ESD protection across the entire glove surface.

Most anti static gloves are designed to be form-fitting, offering dexterity and tactile sensitivity so workers can perform intricate tasks without obstruction. Many are also reusable and machine-washable, making them a cost-effective solution for ongoing ESD control.

How Do Anti Static Gloves Work?

Anti static gloves function by creating a controlled, conductive path that allows static electricity to dissipate safely. By equalizing the static potential between the wearer and the object being handled, these gloves prevent electrostatic discharge events—also known as ESD arcs or “sparks”—which can irreversibly damage sensitive electronic components.

The gloves achieve this through the use of specific materials and construction techniques:

- Conductive fibers: Woven or integrated within the glove material to facilitate static dissipation.

- Carbon coatings or filaments: Provide reliable conductivity and maintain consistent electrical resistance.

- Specialty washes and treatments: Used to ensure the gloves remain free of contaminants that might interfere with ESD control.

- ESD-safe sewing patterns: Ensure that all glove surfaces maintain the necessary resistivity, with no isolated areas prone to charge build-up.

Why Is ESD Protection Important?

Electrostatic discharge can cause immediate or latent damage to sensitive electronics, semiconductors, and microcircuits. Even a tiny static shock—often imperceptible to humans—can destroy integrated circuits, corrupt data storage, or render components unreliable. As such, ESD-safe gloves are a core requirement in any ESD protection program, alongside wrist straps, ESD mats, and ionizers.

Applications and Use Cases for Anti Static Gloves

Wondering when to use anti static gloves or how to choose the right ESD gloves for your needs? Here are some of the most common applications and industries benefiting from static control gloves:

- Electronics Assembly: Preventing static damage during the handling, inspection, and assembly of printed circuit boards (PCBs), microprocessors, and integrated circuits.

- Semiconductor Manufacturing: Ensuring the reliability of wafers and microchips by eliminating ESD risks during production and quality control.

- Medical Equipment Assembly: Protecting sensitive diagnostic and imaging devices from static-related failures.

- Cleanroom Operations: Maintaining strict particulate and static control for pharmaceutical, biotech, and aerospace manufacturing environments.

- Telecommunications: Safeguarding delicate fiber optic and networking components from ESD events.

- Computer Repair and IT Maintenance: Protecting hard drives, memory modules, and internal components during installation or troubleshooting.

- Optical and Photonics Labs: Preventing static-induced contamination or damage to lenses, mirrors, and sensors.

- Electrostatic Painting and Coating: Ensuring a consistent, high-quality finish by eliminating stray static charges.

Who Should Use Anti Static Gloves?

Anyone working with static-sensitive devices or materials should consider ESD-safe gloves as part of their personal protective equipment (PPE). This includes:

- Electronics engineers and technicians

- Computer repair professionals

- Quality control inspectors

- Cleanroom operators

- Medical device assemblers

- Laboratory personnel

- IT support staff

Are you unsure if your application requires anti static gloves? Ask yourself: Does my work involve handling integrated circuits, microchips, or devices with exposed conductive surfaces? If so, ESD gloves are strongly recommended.

Benefits of Using Anti Static Gloves

Integrating anti static gloves into your ESD control program offers a range of benefits, including:

- Protection of Sensitive Electronics: Prevents both catastrophic and “silent” failures caused by static discharge.

- Reduced Product Rejection Rates: Improves overall yield and reduces costs associated with damaged parts.

- Improved Safety and Comfort: Modern ESD gloves are breathable, lightweight, and designed for all-day wear.

- Reusable and Cost-Effective: Most anti static gloves can be laundered and reused, making them an economical choice for ongoing static control.

- Maintains Cleanroom Standards: Specialized ESD gloves are available for ISO and Class 100/1000 cleanroom environments, ensuring low particulate shedding and chemical compatibility.

- Enhanced Grip and Dexterity: Textured or PVC-coated surfaces offer improved handling of small, delicate components.

- Compliance with Industry Standards: Supports compliance with ANSI/ESD S20.20, IEC 61340, and other recognized ESD protection standards.

How to Select the Right Anti Static Gloves

Choosing the best anti static gloves for your application requires careful consideration of several factors:

- Material: Match the glove material (nitrile, carbon, latex, PVC) to your workplace requirements, such as chemical compatibility, allergy concerns, and tactile sensitivity.

- Resistivity: Ensure the gloves offer the appropriate surface resistance (typically 105–109 ohms) for your specific ESD protection needs.

- Fit and Size: Select gloves that fit snugly without restricting movement. Most manufacturers offer sizes from small to large, and some provide extra-small or extra-large options.

- Reusable vs. Disposable: Determine if you need gloves for single-use (to avoid contamination) or if reusable, washable gloves are suitable for your environment.

- Industry Certifications: Look for gloves tested and certified to relevant standards, such as ANSI/ESD, IEC, or ISO cleanroom requirements.

- Grip and Dexterity: Consider gloves with textured or coated surfaces for applications requiring precise handling.

- Bulk Purchasing: Many suppliers offer discounts for bulk orders—ideal for outfitting large teams or facilities.

Still trying to find the right ESD gloves for your unique needs? Explore:

- What are the best anti static gloves for electronics assembly?

- Which gloves are suitable for cleanrooms or medical device manufacturing?

- Are there latex-free or hypoallergenic anti static gloves available?

- What glove resistivity is required for your ESD-sensitive environment?

- How do you properly care for and maintain reusable anti static gloves?

FAQs: Frequently Asked Questions About Anti Static Gloves

How do I know if I need anti static gloves?

If your job involves working with printed circuit boards, microchips, hard drives, or exposed electronics, anti static gloves are essential for preventing ESD damage. They are also recommended for cleanroom, laboratory, and medical equipment assembly where static control is critical.

Can anti static gloves be washed and reused?

Yes, the majority of ESD gloves are reusable and can be washed according to the manufacturer’s instructions. Regular cleaning helps maintain their conductivity and prolongs glove life. Always check for wear or damage after each wash.

Are there different types of anti static gloves?

Yes, anti static gloves come in a variety of materials and designs, including nitrile, carbon fiber, latex, PVC-coated, and specialty cleanroom gloves. Some are powder-free, latex-free, or designed for extra grip and dexterity. Always select the type that best matches your work environment and static control requirements.

Can I use regular gloves instead of ESD-safe gloves?

Regular gloves do not provide the necessary static dissipation and may even increase the risk of static discharge. Only gloves specifically labeled as “anti static,” “ESD-safe,” or “static dissipative” should be used for electronics and static-sensitive applications.

What other ESD protection products should I consider?

In addition to anti static gloves, it’s important to use wrist straps, ESD mats, ionizers, protective clothing, and heel grounders to create a comprehensive static control system.

Ordering and Sourcing Anti Static Gloves

When searching for where to buy anti static gloves or ESD gloves in bulk, consider reputable industrial suppliers, specialty ESD equipment providers, and online distributors. Many manufacturers offer a range of glove models tailored for different industries, from precision electronics to pharmaceuticals.

Looking to compare anti static glove prices or request a quote for bulk orders? Use search queries like:

- “Buy anti static gloves for electronics assembly”

- “Bulk ESD gloves for cleanroom use”

- “Order static dissipative gloves online”

- “Best ESD-safe gloves for semiconductor manufacturing”

- “Anti static gloves suppliers near me”

Many suppliers also provide product datasheets, resistivity test results, and compliance certifications to help you make an informed purchasing decision. Be sure to review product specifications and consult with ESD experts to ensure you’re selecting gloves that meet your facility’s requirements.

Best Practices: Using and Maintaining Anti Static Gloves

Proper use and care of anti static gloves is essential for maximizing ESD protection and glove longevity. Here are some expert tips:

- Inspect gloves before each use for signs of wear, holes, or contamination.

- Wash reusable gloves regularly according to manufacturer guidelines.

- Store gloves in a clean, dry area away from direct sunlight and chemicals.

- Do not use gloves that have lost their conductivity or are visibly damaged.

- Pair gloves with other ESD protection devices, such as wrist straps and grounded mats, for comprehensive static control.

- Train all staff on the importance of ESD control and proper glove use.

How to Test Anti Static Gloves

Periodically verify glove resistivity using a surface resistance meter to ensure continued ESD protection, especially in high-reliability environments like semiconductor fabs and cleanrooms. Replace gloves that no longer meet specified resistance ranges.

Conclusion: Why Invest in Anti Static Gloves for Static Control?

Anti static gloves are a foundational component of any static control strategy. By protecting sensitive electronics, medical devices, and precision equipment from ESD damage, these gloves help ensure product quality, safety, and regulatory compliance. Investing in the right ESD-safe gloves reduces the risk of costly failures, increases workplace safety, and supports efficient manufacturing processes across a wide range of industries.

Ready to find the best anti static gloves for your facility? Browse leading static eliminator manufacturers or explore ESD protection solutions today.

For more detailed product information, application advice, or bulk ordering options, contact a trusted ESD supply partner or request a free consultation.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

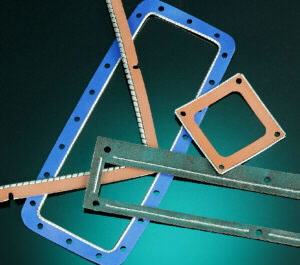

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

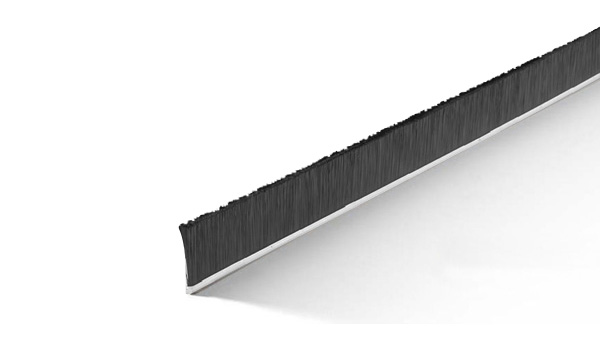

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services